18.06.2024 / Press Release

Family festival at MAHA

MAHA once again organised a festival for the whole family on its company premises. Curious ...

more details... and we have set off fireworks for you!

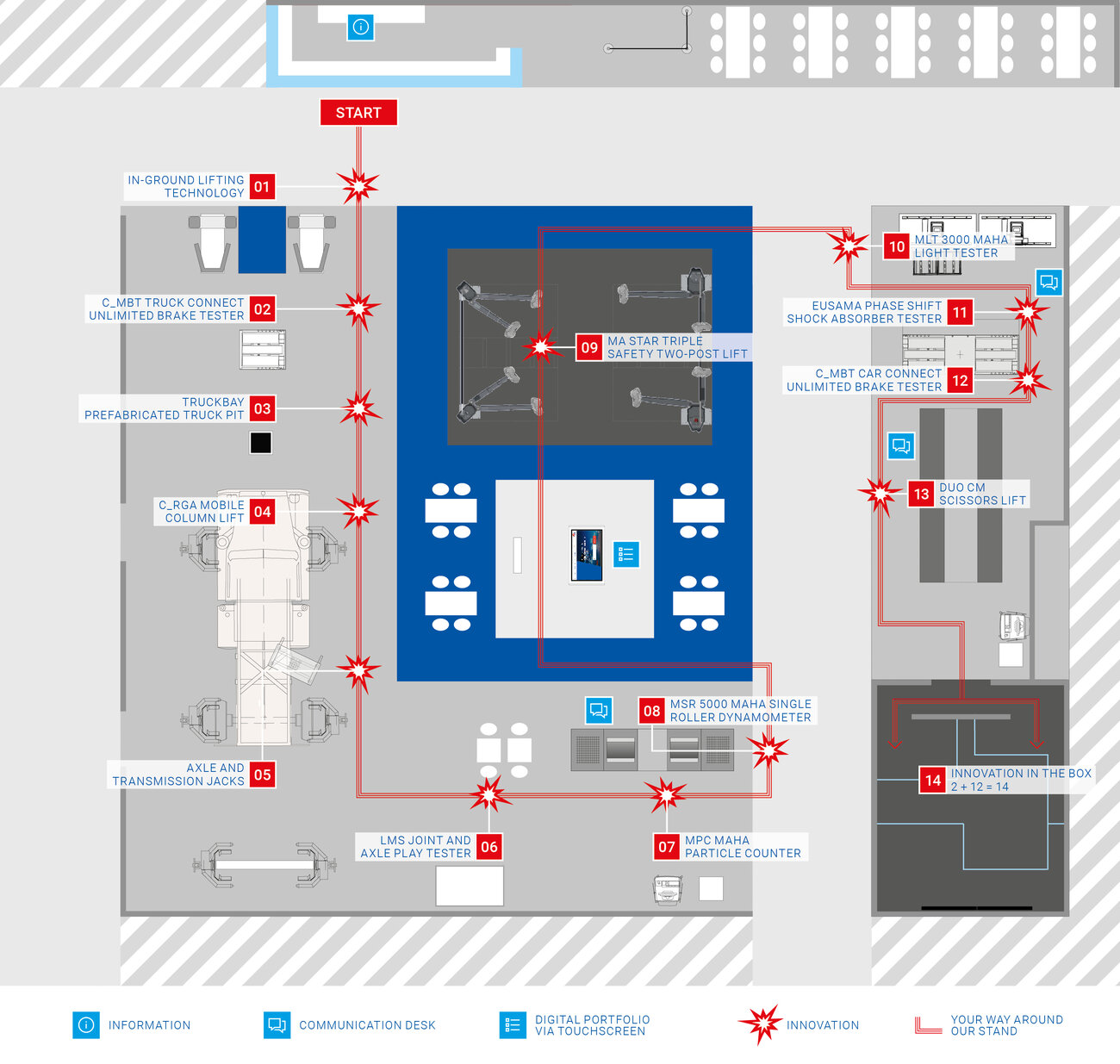

Experience our innovations!

More about our innovations and "Coming Soon - Products".

Tried and tested in-ground lifting technology with special supports for a wide variety of electric vehicles with patent-pending, spring-guided quick positioning.

Lift with swing arm supports

Lift with flat head supports

Brake tester TRUCK CONNECT – innovation of the decade – world’s first digital brake tester with state-of-the-art network technology – more details in our “Innovation Box”.

Truck testing and working pit – tailor-made according to the customer’s needs, can be easily and quickly installed on site and combined with all kinds of equipment.

World’s first mobile column lift with lithium-ion battery technology and with unique, interference-free radio operation with double safety.

Latest generation pit jacks with synchronised cylinder and Venturi nozzle, which guarantee safe and accurate work.

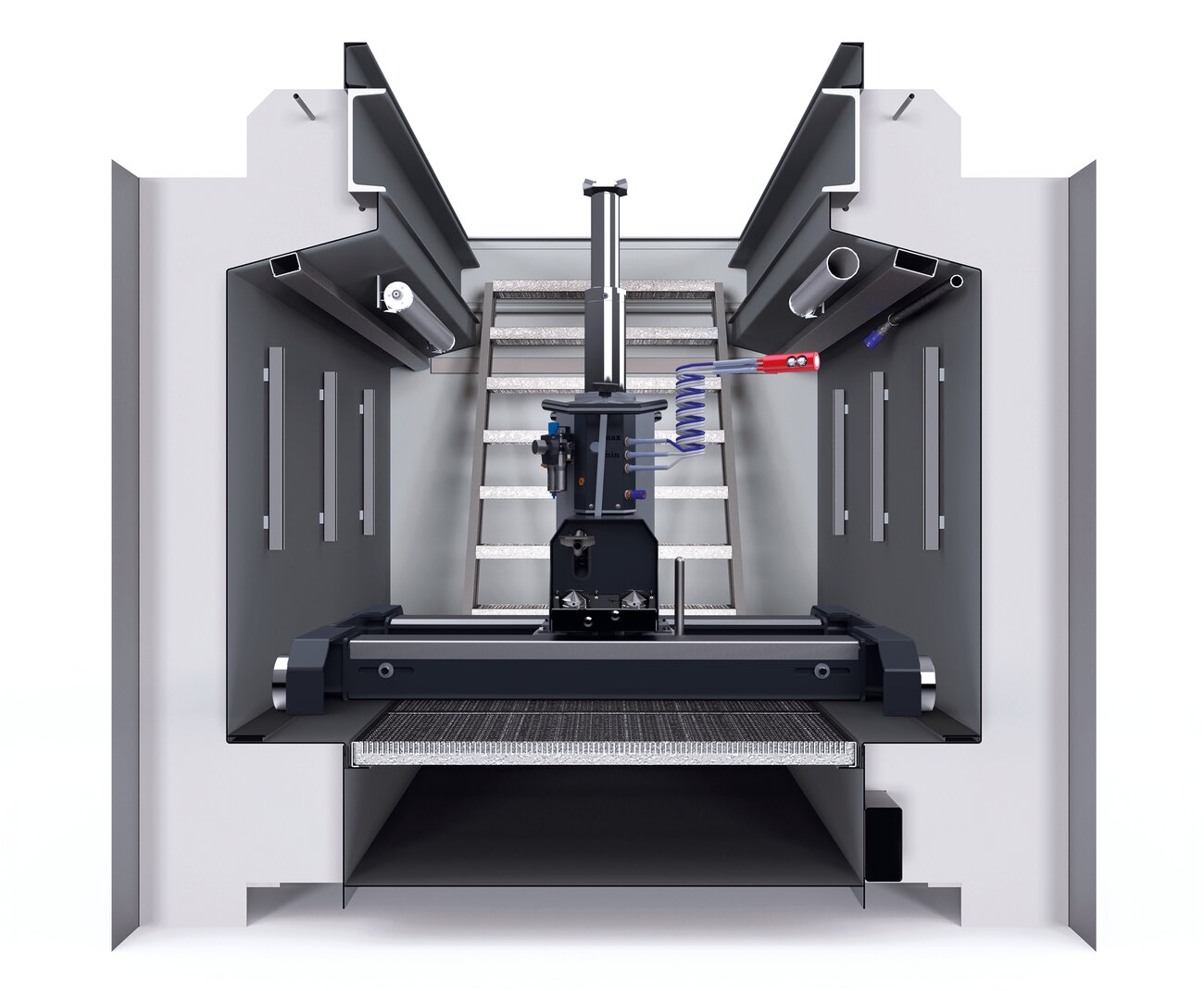

Truck axle play tester model with up to 20 t axle load, in which the current EU directive 2014/45/EU has already been implemented.

State-of-the-art particle measurement counter for both diesel and gasoline vehicles, based on the operating fluid-free diffusion charging measurement principle.

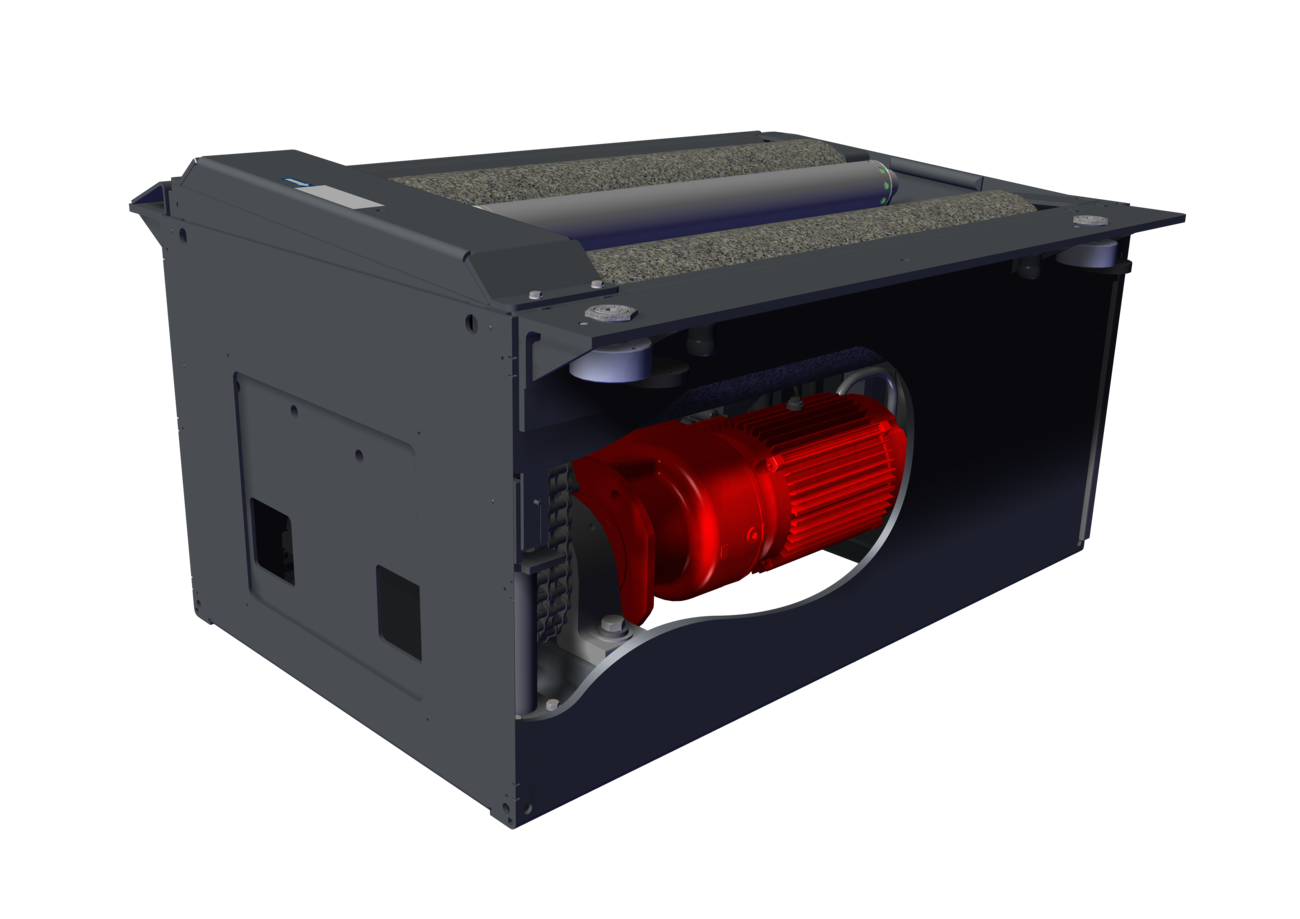

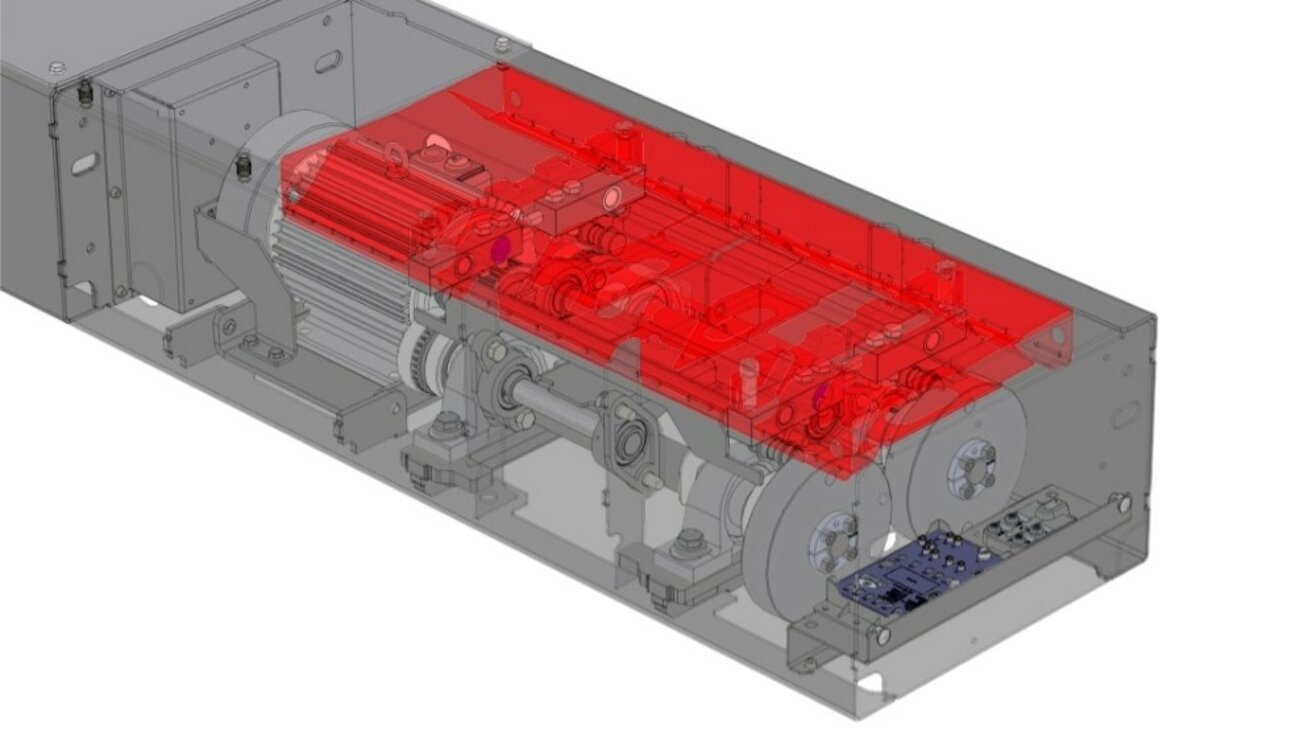

Performance meets precision – the completely new development is based on a PLC-programmed dynamometer and guarantees precise, reliable and reproducible measurement results.

Unique in design and safety – the two-post lift family MA STAR triple safety with 3.5 t, 5.5 t and brand new with 6.5 t load capacity.

The redesign of the MLT 3000 is characterised in particular by the faster image processing of the new camera and control and can inspect the latest headlight technology.

COMING SOON!

MLT 3000

This new development meets the recommended specification of the EGEA (European Garage Equipment Association) and operates according to the phase shift principle

Brake tester CAR CONNECT – innovation of the decade – world’s first digital brake tester with state-of-the-art network technology – more details in our “Innovation Box”.

DUO CM scissors lifts with two different runways, on the one hand according to the German directive for headlight testing stations, and on the other hand according to the new EU directive for axle play testers.

The product innovation of the decade - making good things even better. Using the platform of our excellent brake testers with more than 50 years of experience, MAHA has created a new generation that stands out.

10 out of 10 reasons

that speak for the new CONNECT.

CONNECT unlimited.

EVERYTHING IS POSSIBLE.

CONNECT SERIES - only PROS, no CONS

CONNECT unlimited.

EVERYTHING IS POSSIBLE.

The CONNECT CUBE V3 - another milestone in MAHA's digitisation strategy. Different IT infrastructure, interface configuration, export and import function or complex network configuration are a thing of the past, because the CONNECT CUBE V3 simplifies your daily work enormously. It can be used as a mobile data node for all ASA livestream-capable brake testers of the manufacturers represented on the market. Plug'n'Play has never been easier. A further feature of the CONNECT CUBE V3 is its use during the safety test (SP) and the main inspection (HU) according to § 29 StVZO. Existing brake test stands that have an ASA livestream interface can be extended with the CONNECT CUBE V3 to include a digital display on laptop and smartphone. This is done via the usual browsers or with the integrated HDMI port for screen display.

The solution - made by MAHA: The CONNECT CUBE V3

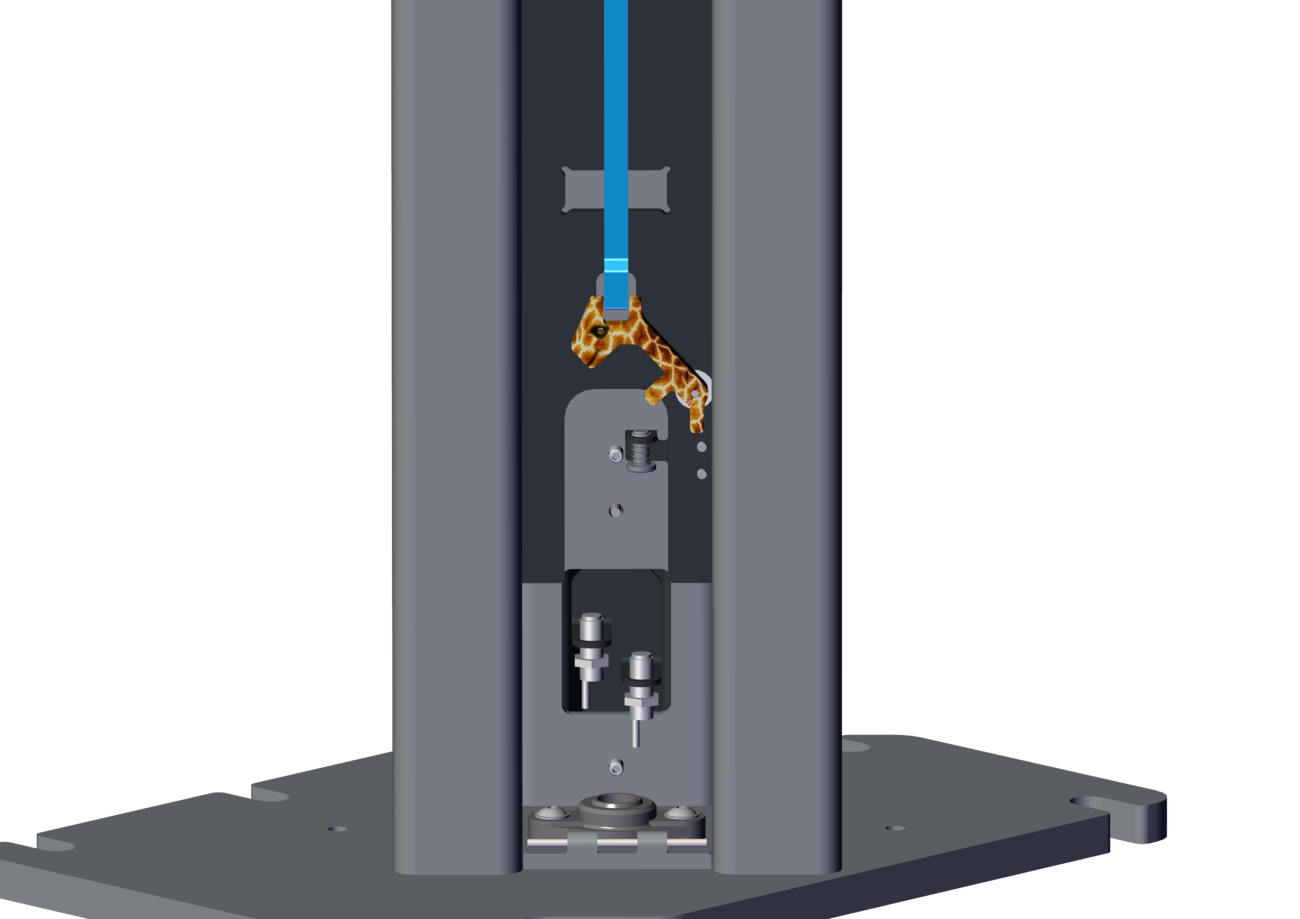

At the beginning of the year 2020, the world market leader MAHA launched its latest product at a national and international product event. The MA STAR triple safety***** two post lift with 3.5 t load capacity boasts triple safety and five stars for competitive value for money.

The stable and solid design, the safety of use, the straightforward maintenance and service, the simple commissioning and the intuitive operation each earn one star. Furthermore, the four registered patents are evidence of the worldwide technological leadership of MA STAR triple safety*****.

This new lift concept has been excellently accepted by the market. Several hundred units have already been sold in a very short time. At the beginning of 2021, the "big brother" with 5.5 t load capacity was launched..

MA STAR triple safety ***** – A product that deserves its five stars, the MA STAR

The rails made of stainless steel and the mounting material guarantee a sustainable investment and long service life. Our modular stainless steel rails are characterised by individual possibilities for above and below ground installation - both in new buildings and retrofits - as well as by the traversability with up to 18 t axle load.

Since February MAHA offers a state-of-the-art device to calibrate and adjust brake test stands even more efficiently. The new special tool is compatible with all MAHA brake testers and can be used for motorcycles, passenger cars and truck variants alike. Thanks to its compactness, the multifunctional device is also incredibly easy to handle.

MAHA already meets the new requirements of the European Directive 2014/45/EU 100%. This directive for truck and car axle play testers must be implemented by customers by 20 May 2023 at the latest. The LMS and PMS product lines thus meet the requirement of synchronous movements of both test plates in longitudinal and transverse direction in a targeted and successful manner. Additionally for vehicles > 3.5 t (permissible total weight) travel of the test plates min. 95 mm and test plate speed min. 5 cm/s.

The following axle play testers are now available for the customer.

MAHA is happy to present its new software product: “EUROSYSTEM V8”. This unique solution simplifies a number of periodic vehicle testing procedures so that they can be carried out faster – in more than 40 different countries, thanks to its modern user-friendly and intuitive operating panel.

Reduced to the essentials – made by MAHA

Excellent depiction and evaluation of all relevant measurement values – made by MAHA

One test station, two tests – from two to one. The practical advantage: it would enable measurement of both nitrogen oxide (NOx) emissions under load and vehicle brake efficiency with one and the same test station in the future.

Special requirements demand special solutions. The headlights of the new VW Touareg are tested worldwide only with MAHA headlight testers. MAHA is the first and so far only supplier to receive the official group-wide manufacturer approval from Volkswagen AG for testing and adjusting the headlights of the new VW Touareg.

With our technologies, we at MAHA are actively helping to make the mobility of tomorrow as safe, reliable and environmentally friendly as possible. So it’s only logical that we produce the best solutions with maximum safety in terms of vehicle testing and workshop equipment.

After all, our experience, passion and innovative spirit are reflected in even the smallest detail. And it’s going to stay that way. Because as a foundation, we’re perfectly positioned to face the future. What we generate flows back into our company as a solid investment – for even more innovations, for example.